Determining the Completion of Freeze-Drying: A Comprehensive Guide

The Freeze drying process, or lyophilization, is a critical preservation technique utilized across various industries, essential for achieving product stability and longevity and shelf life of food. As such, accurately pinpointing the completion of the freeze drying process is crucial.

This guide explores various methodologies ranging from basic visual checks to advanced scientific analyses to ensure precise determination of this endpoint. So you know how to determine when freeze drying process is complete. We will explore the methods, some depend on the type of product you need to freeze dry and some have to do with the advancement of the freeze dryer you have at your disposal.

In the realm of preservation technology, freeze drying stands as a pinnacle, preserving the integrity and efficacy of perishable materials across diverse fields. From pharmaceuticals to gourmet delicacies, its role in ensuring product stability and longevity is unparalleled. Yet, amidst its sophistication lies a critical challenge: accurately identifying when the freeze drying process reaches completion.

We will delves into the intricacies of determining freeze drying completion, exploring methodologies ranging from simple visual inspections to sophisticated scientific analyses. Whether you’re preserving delicate biological samples or crafting culinary delights, understanding these methods is essential for achieving optimal results. Join us as we navigate the nuances of freeze drying completion, empowering you to master this critical aspect of preservation technology.

Understanding the different steps of the Freeze drying process:

(Pre) Freezing:

In this phase, the material to be dried needs to be frozen. This is one of the most critical phases. There are differed ways to freeze, Slow freezing and rapidly freezing.

Freezing can be achieved using various methods such as immersion in a cold bath or by using freezing plates. The goal is to convert water in the material from a liquid to frozen water molecules in a solid state.

It all depends on what you like to freeze drier. The freeze drying time is shortened by freezing the material slow this will produces large ice crystals. But with biological materials these large ice crystals can damage cell walls and could brake the structure of those cell walls. This will effect your final quality. So for biological materials it is best to Rapidly freezing, you can even do this with liquid nitrogen

Rapidly freezing will minimize the formation of large ice crystals, those smaller ice crystals will evaporate slower causing the primary and secondary drying to take more time. So you need to adjust your drying methods to the way your product are frozen.

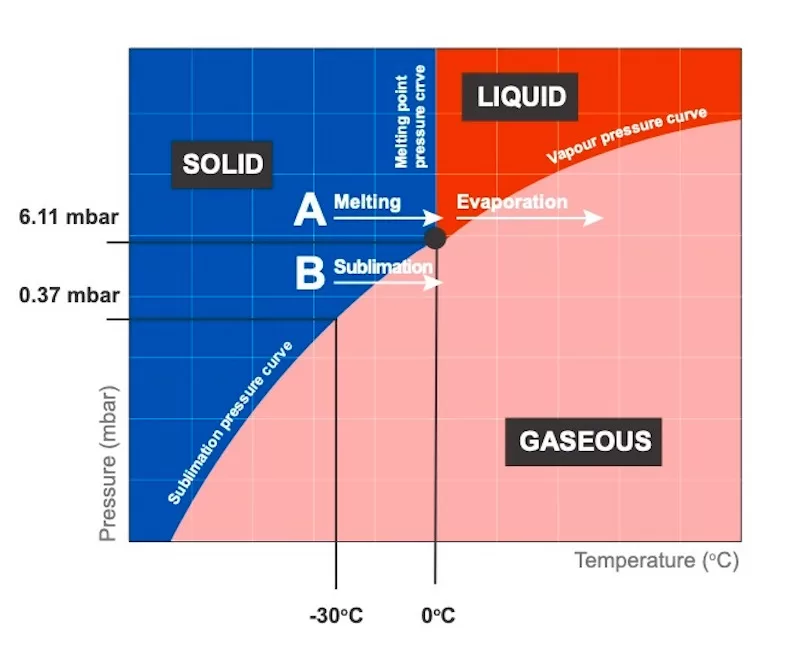

Primary Drying phase (Sublimation):

Once the material is frozen, we go to the second step in the freeze drying process the primary drying phase.

The pressure in the drying chamber is then reduced, and heat is applied. This causes the frozen water (ice) to undergo sublimation, transitioning directly from a solid to a vapor phase without passing through the liquid phase.

This is commonly known as the Primary drying phase. Sublimation removes the majority of the water from the material. The temperature and pressure conditions are carefully controlled to ensure the efficient removal of water while preserving the integrity of the material.

Secondary Drying (Desorption):

In this final phase, any remaining bound water molecules are removed from the material. This is the secondary drying phase and is typically achieved by increasing the temperature and lowering the chamber pressure further to encourage the desorption of the water molecules from the material’s structure.

The goal is to reduce the moisture content to a level where the material remains stable during storage and usage. This secondary drying step is the fastest, it approximately takes one-third to half of the drying time that is required for the primary drying phase.

Methods of measuring

Cycle Time Analysis

Cycle time serves as a fundamental metric in assessing the completion of freeze-drying. This method is especially prevalent in pharmaceutical settings where advanced freeze dryers are used.

Operators of the freeze dryer preset a specific duration covering both the freezing and primary drying phases, and secondary drying phase akin to using a timer, which ensures that the products undergo necessary changes and reach an ideal dried state efficiently.

Visual Inspection

Particularly in simpler freeze dryer setups like manifold dryers, visual inspection is a commonly used method to assess whether products are thoroughly dried with the freeze dryer. However, this technique has significant drawbacks:

Subjectivity: Results can vary between observers, which may conflict with the stringent accuracy requirements of regulated environments.

Lack of Quantitative Data: Visual methods provide qualitative rather than quantitative insights, offering no data on crucial aspects such as moisture content.

These limitations highlight the necessity for integrating more objective, data-driven methods alongside visual inspection to accurately evaluate the drying process.

Moisture Content Analysis

Advanced freeze-drying machines incorporate comprehensive moisture content evaluations using analytical techniques like Karl Fischer titration. Such in-depth analysis is instrumental in confirming that the residual moisture content meets specific requirements, thereby indicating the end of the drying process.

Continual moisture monitoring during freeze drying offers real-time updates that help fine-tune the process to achieve optimal product stability.

Weight Monitoring as an Indicator of freeze Drying Progress

Monitoring the weight change of the product is an effective strategy to determine the end of the freeze-drying process. This method can be implemented after the drying or in real-time using specialised scales capable of tracking a product’s weight throughout the cycle.

A stable weight suggests that the target dryness has been achieved. However, it’s important to note that these real-time weight measurement systems are often expensive and typically limited to monitoring just individual samples and not all the products in the freeze dryer at that time. This limited their widespread use.

In-Process Monitoring for Precision Control

Utilizing advanced in-process monitoring technologies, modern freeze dryers offer meticulous control over the freeze drying process through the following methods:

Temperature and Pressure Checks:

Temperature sensors track the gradual increase in product temperature, which should eventually match the shelf temperature, signaling the cessation of sublimation. Simultaneously, sophisticated devices like Pirani and Capacitance manometers provide detailed pressure profiles crucial for understanding the drying phase dynamics.

Mass and Heat Flow Metrics:

These measurements are vital for observing the rate of water vapor removal and heat consumption, allowing for immediate process adjustments to enhance efficiency and product quality.

Conclusion: Mastery of Freeze-Drying Completion

Mastering the determination of freeze-drying completion is a blend of art and science, incorporating straightforward methods like visual inspection and complex technologies such as in-process monitoring and moisture content analysis.

By choosing the appropriate combination of these techniques, one can ensure the highest quality and stability of freeze-dried products. Whether in a laboratory setting or industrial scale, understanding these methods enriches the capability to deliver a precise drying process.

How do I know when freeze-drying is complete with your Holland Green Science Xiros Mikro freeze Dryer?

How to development you own prefect freeze drying method;

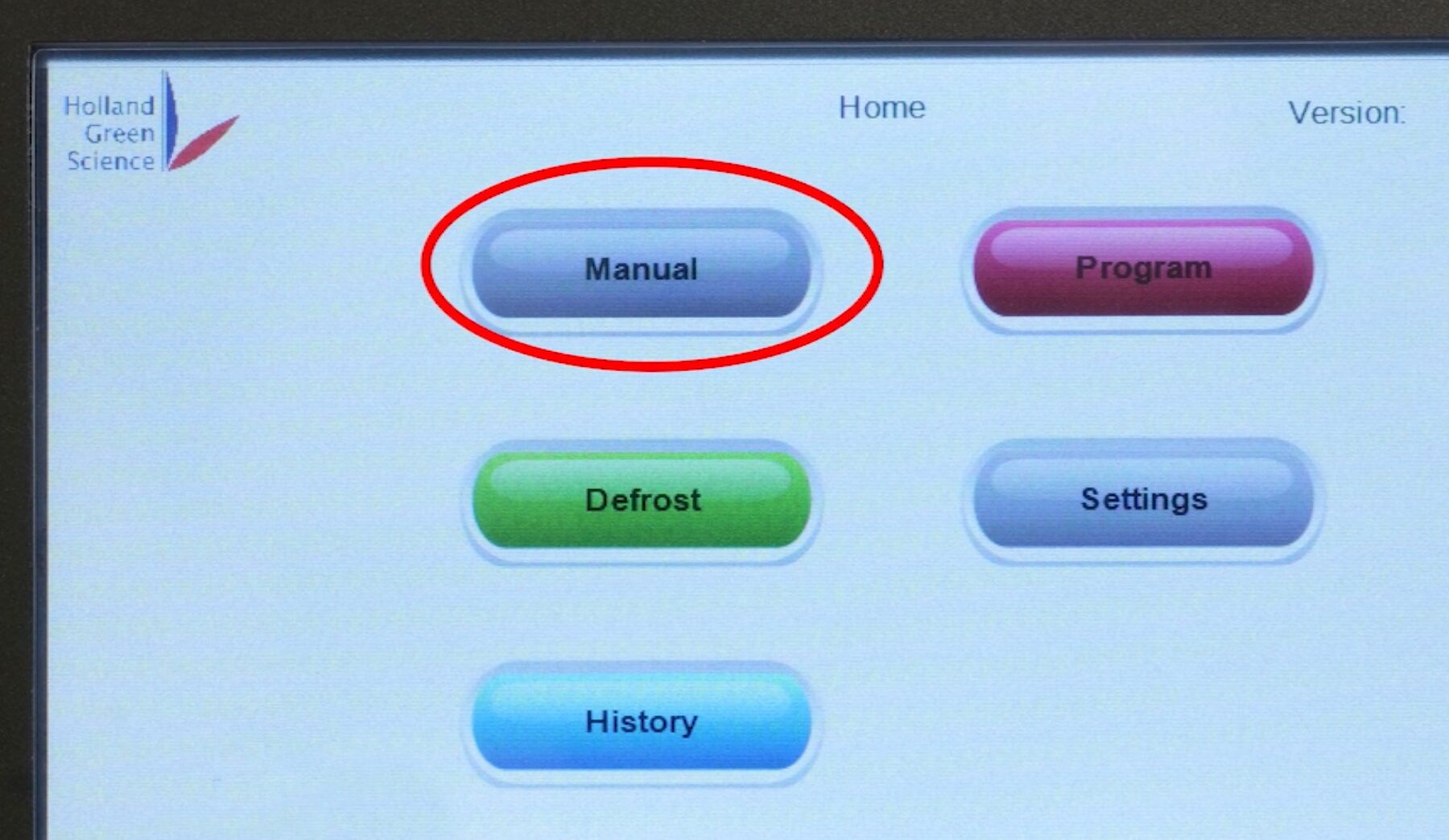

For a proper freeze drying process and to determine what program settings are best used for freeze drying your product, we first need to determine what settings are best for freeze drying the product. A easy way to do determine this, is to first use the Xiros Mikro ‘manual mode’ option (start screen shows this button).

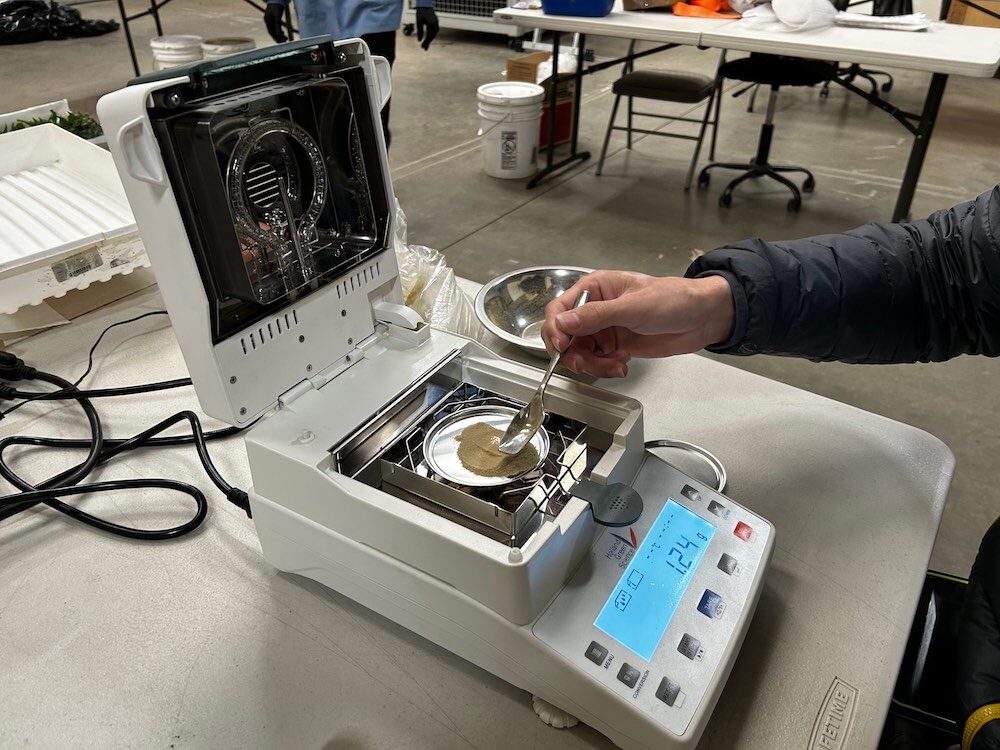

You first need to weigh the empty trays with a scale, and use a scale with a readability of minimum of 1 gram.

Then you can weigh the trays with the product you are going to freeze dry.

Next step is to put the trays onto the shelves of the Xiros Mikro freeze dryer. Turn the freeze dryer on and select ‘manual mode’. In manual mode turn the manual control to ON (at the top of the screen). Make sure the door and the drain valve are properly closed. turn the compressor on to start the pre-freeze.

Tip: you can already switch on the Xiros Mikro freeze dryer and start the cooling process before you put the products in your freeze dryer. This will shorten the total freeze drying process since your freeze drying chamber will be cold before you place the products into the chamber.

Pre-Freeze

Pre-freeze or freezing stage inside the freeze dryer generally takes 6 up to 8 hours. Depending on the freezing temperature, ambient temperature and the condenser temperature. When pre-freeze is completed, you can go ahead and start the primary drying phase.

Tip: To speed up your freeze drying, you can pre freeze your product in an external freezer. It’s best to have the frozen material on the trays in the external freezer. This allows you to jump immediately to the primary drying phase.

Primary drying phase

Primary drying is the sublimation stage, This process will convert the ice directly into a gas without melting, so there is no liquid water involved in this type of evaporation.

The product is held at a temperature lower than the eutectoid of the ice and controlled negative chamber pressure is used to remove the vapor.

To start primary drying, set both shelve control temperatures and the system control vacuum to the desired setpoints.

Turn on the vacuum pump and vacuum valve and switch on the lower and upper heaters.

To check if primary drying is complete, you can pause the primary drying phase.

Turn off the vacuum valve and the vacuum pump. Then slowly open the drain valve (make sure the hose is not connected to the drain valve) this will result in the chamber to go back to atmospheric pressure, now you can open the door and weigh the trays again.

Now you still don’t know your freeze dried material is fully dry, you first need to put the trays back onto the Xiros Mikro freeze dryer. Make sure the door and the drain valve are properly closed. Now you can switch on the vacuum pump and open the vacuum valve again.

Repeat the weighing process after approximately 2 hours. If the weight is stable, then the primary drying phase is completed, if not you need to repeat the last steps until you get the same weight results.

When the primary drying phase is completed, you can go ahead and start the secondary drying phase.

Tip: Heat sensitive materials can be slowly heated with the Xiros Mikro. At a low temperature even a minus/negative temperature, just as long as there is a positive temperature difference between the shelf temperature and the chamber temperature there will be sublimation.

Secondary drying phase

Secondary drying, the temperature is increased to evaporate adsorbed water (desorption) that did not freeze during the first stage of the process.

To start secondary drying, set both shelve control temperatures and the system control vacuum to the desired setpoints.

To check if secondary drying is complete, you can pause the secondary drying phase. The procedure of the primary and secondary drying are similar steps;

Turn off the vacuum valve and the vacuum pump. Slowly open the drain valve (make sure the hose is not connected to the drain valve) now you can weigh the trays again.

Then put the trays back onto the shelves of the Xiros Mikro freeze dryer. Make sure the door and the drain valve are properly closed.

Turn on the vacuum pump and vacuum valve again (via the touchscreen control) and repeat the weighing process after approximately 2 hours. If the weight is stable the freeze drying process is completed (otherwise repeat the last steps).

Tip: You can also use an infrared thermometer or infrared camera to see if all products on the shelves have reached the desired temperature confirming the freeze drying process is completed.

Conclusion of this process development:

With this Manual method, you can calculate your setpoints and dry times needed to enter them into one of the four automatic programs that are available on the Xiros Mikro freeze dryer. This program is immediately saved onto your Xiros Mikro freeze dryer and can be reused again and again to run your freeze drying or sublimation process. Making the drying process automatic, combining the primary and secondary drying phase all in one easy to use program.

The Xiros Mikro allows you to enter up to 16 different steps per program, in those steps, you can adjust; the duration of the step, the vacuum and the temperature in that step. This allows you to perfectly dry literally anything from freeze dried strawberries to delicate heat-sensitive materials. Resulting in the best freeze dried product you will find.