Freeze drying is a popular technique used in various industries such as food, pharmaceutical, and biomedical research. It is a reliable method that removes moisture from a product while preserving its natural flavor and aroma.

The process of freeze drying starts by placing the product in the vacuum chamber, in the freeze dryer and lowering the temperature to below freezing point. The dryer then slowly heats the ice to boiling point and extracts it as vapor. The extremely low pressure in the freeze dryer causes the ice to transition directly from a solid into a gas.

Our Holland Green Science Xiros high-performance freeze dryers, are essential in facilitating this process. These freeze dryers ensure that the gas is captured and extracted from the system while the product maintains its good qualities. For example, with freeze dried food: the Xiros high-performance freeze dryer preserves the taste, texture, and nutritional value of food.

Freeze Drying: How, where, when?

So, freeze drying is a technique that removes moisture from a product while retaining its natural structure, taste, aroma, and nutritional value. As said before, this technique is popular in the food, pharmaceutical, and medical industries. Freeze drying is used to preserve fruits, vegetables, and meat products. Freeze dried food, such as fruits (think of freeze dry berries) and vegetables are a popular snack, while freeze dried meat products are used in military rations. Food out of the freeze dryer is perfectly suitable for long-term storage. In the pharmaceutical industry, freeze drying is used to preserve vaccines, antibiotics, and other medications. The process ensures that the medicine remains stable and effective for longer periods. In the medical industry, freeze drying is used to preserve blood plasma, tissues, and other organic matter.

Freeze Drying: the method

How does a freeze dryer work: if you place your product inside the vacuum chamber of the machine, then the freeze dryer takes care of lowering the temperature to the point where the water content of the product freezes: for example, in our Xiros Mikro Freeze dryer at a temperature below -40 °C. Next, the vacuum chamber lowers the pressure, causing the frozen water molecules to sublimate, or go directly from a solid to a gas, bypassing the liquid state. The vacuum chamber then collects the gas state of the extracted water vapor, leaving behind a perfectly dehydrated product. The freeze drying process is a delicate balance of time, temperature (cold and heat), and pressure. The product can be damaged or ruined if any of these factors are off. Therefore, it is essential to have a well-maintained and calibrated freeze dryer.

Freeze Dry Machine: Key Components

A Freeze dryer contains several components:

- the vacuum chamber,

- a refrigeration system,

- the condenser,

- the control system

- and the vacuum pump.

The vacuum chamber is the central space of the freeze dryer, where the product is frozen. The refrigeration system is responsible for cooling and maintaining the temperature inside the chamber. The condenser collects the water vapor, and the control system, regulates the process regarding, pressure, temperature, and time.

The vacuum pump is also an essential component of the process. The pump is responsible for creating the vacuum inside the chamber. The vacuum is necessary for the sublimation process to occur. The vacuum pump must have enough capacity to maintain a low enough pressure for the water molecules to sublimate. At Holland Green science Europe, we offer a variety of vacuum pumps, Why? You can find the advantages of a separate vacuum pump, and all our vacuum pumps here.

Freeze drying is a complex technique that involves a delicate balance of time, temperature, and pressure. Freeze dried food is emerging and the method is also popular in the pharmaceutical, and medical industries. To ensure a successful freeze drying process, it is essential to have a well-maintained and calibrated freeze dryer with all the necessary components and with the right capacity.

Freeze Dry Machine: the advantages

Freeze dried food: Preserving Nutritional Value

The key advantage of using a freeze dryer is the ability to retain the product’s nutritional value. Freeze drying preserves the taste, texture, nutrients, and flavor profile of the for example freeze dried food. This makes freeze drying an effective method of keeping food items without altering their taste or nutritional value. For example, fruit out of the freeze dryer retains its vitamins and minerals, making it a healthy snack. Also, freeze dried meat retains its protein content, making it a good option for hikers and campers who need a lightweight source of protein.

Freeze dried food: Extending Shelf Life

Many freeze dried products have a shelf life of up to 30 years, much longer than their original equivalents. This makes freeze drying an ideal solution for long-term food storage. For example: freeze dried meals are a popular choice for emergency supply and survival situations, as they can be stored for long periods without spoiling or losing their nutritional value.

Freeze dried food: Reducing Food Waste

Freeze dried food can be preserved resulting in less waste. The process reduces spoilage and food waste, crucial for companies looking to operate sustainably. Also, freeze drying can preserve leftover produce from farms, reducing food waste and providing an additional revenue stream for farmers.

Freeze dried food: Maintaining Flavor and Texture

Freeze dried products maintain their taste and texture and often provide a better visual and sensory appeal than traditionally preserved items. For example: freeze dried herbs and spices retain their flavor and aroma, making them a popular choice for chefs and home cooks. Freeze dried fruits and vegetables also maintain their texture, making them a great addition to salads and other dishes.

Freeze Drying: Applications

By now, you know freeze drying is adaptable and has several uses in various industries. The following is a list of the most common uses of freeze drying:

Food Industry

Freeze dryers are commonly used in the food industry to make the food last longer on the shelf. The freeze dryer is also used to create unique food items such as freeze dried fruits that can be used for snacking, baking, or incorporated in cereals and other products.

Freeze drying involves removing water from the food uniquely, which helps prevent spoilage and the growth of bacteria. This makes it an ideal preservation technique for foods prone to spoiling quickly, such as fruits, vegetables, and meats. Freeze dried foods are also popular among hikers and campers, as they are lightweight, easy to carry and store and have a long shelf life. They are a convenient option for people who need to pack food for extended outdoor trips.

Pharmaceutical Industry

Our freeze dryer is an essential tool for producing vaccines, antibiotics, and other medications in the pharmaceutical industry. It allows for the preservation of the drug’s active ingredients and increases the product to last longer on the shelf.

Freeze drying is a gentle process that helps maintain the drug’s efficacy while removing water from the product. This makes it an ideal technique for preserving sensitive drugs that other preservation methods may damage. Our freeze dryer also creates powdered medications that can be easily reconstituted with water. This makes it easier for patients to take their medication, especially those who have difficulty swallowing pills.

Biotechnology Industry

Freeze dryers are crucial in the biotechnology industry, where they are used for biomass preservation, stabilization of enzymes, and cell culture preservation, among other applications.

Biological samples are often sensitive to changes in temperature and humidity, which can cause the samples to degrade quickly. Our freeze dryer helps to preserve these samples by removing water from the product, which prevents the growth of bacteria and other forms of degradation. The freeze dryer is also used to protect enzymes and other proteins, often used in research and biotechnology applications. By removing water from the product, freeze drying helps to stabilize these proteins, which can be easily reconstituted with water when needed.

Emergency Preparedness and Outdoor Activities

Our freeze dryers are also popular for emergency preparedness, commonly used to create survival food items that can last for an extended period. Freeze drying is also used to develop high-calorie meals designed for outdoor enthusiasts that are lightweight and compact to carry.

Survival food items from the freeze dryer are popular among people who want to be prepared for emergencies such as natural disasters or power outages. These foods can be stored for long periods without spoiling and are easy to prepare through rehydration when needed.

Freeze dried meals are also popular among hikers, campers, and other outdoor enthusiasts. These lightweight and compact meals make them easy to carry and store on extended trips. They are also high in calories, which is important for people who need to maintain their energy levels during physical activity.

Choosing the right freeze dryer

We can’t say it enough, Freeze drying is an ingenious method that involves removing water from a product by sublimation. Summarizing the above: freeze drying is used in various industries, including food production, pharmaceuticals, and research institutions. When choosing the right freeze dryer, there are several factors to consider.

Freeze Dryers: types

There are different types of freeze dryers in the market. The two main categories are bench-top and large-scale commercial machines. Bench-top models are ideal for small-scale food production, and they are often used in laboratories, small businesses and as home freeze dryer (home use). For example: our Xiros Mikro freeze dryer, this freeze dryer is manufactured so compact and small that it is also usable as home freeze dryer for home use, and it also has the capabilities of,- and the high-performance techniques of a laboratory machine.

Large-scale commercial models, including international food manufacturers, pharmaceutical companies, and research institutions, are designed for commercial operations.

Another type of freeze dryer for sale is the mobile freeze dryer. This type of machine is designed for on-site freeze drying and is often used in remote locations. Mobile freeze dryers are ideal for emergency response, military operations, and field research.

Freeze dryers: factors to consider when choosing

When buying a freeze dryer, it’s essential to consider several factors:

- the type of product,

- the size of the batch,

- the quantity of the product being processed,

- energy efficiency,

- the capacity of machinery,

- and how easy it is to operate.

Choosing the right freeze dryer can ensure the right outcome in terms of product quality and economic viability. Other factors to consider include the cost of the machine, the maintenance requirements, and the level of automation. Some devices require manual operation, while others are fully automated.

Freeze dryers: Top Brands and Models

There are several high-quality brands and models of freeze dryers in the market. Our favorite brand is Xiros Mikro. This brand offers a range of models to suit different needs and budgets.

The Xiros Mikro is a popular choice for a home freeze dryer and small-scale food production. It is compact, easy to use, and energy-efficient. Xiros also has large-scale commercial freeze dryers that are designed for high-volume production. It is fully automated and can handle large batches of products.

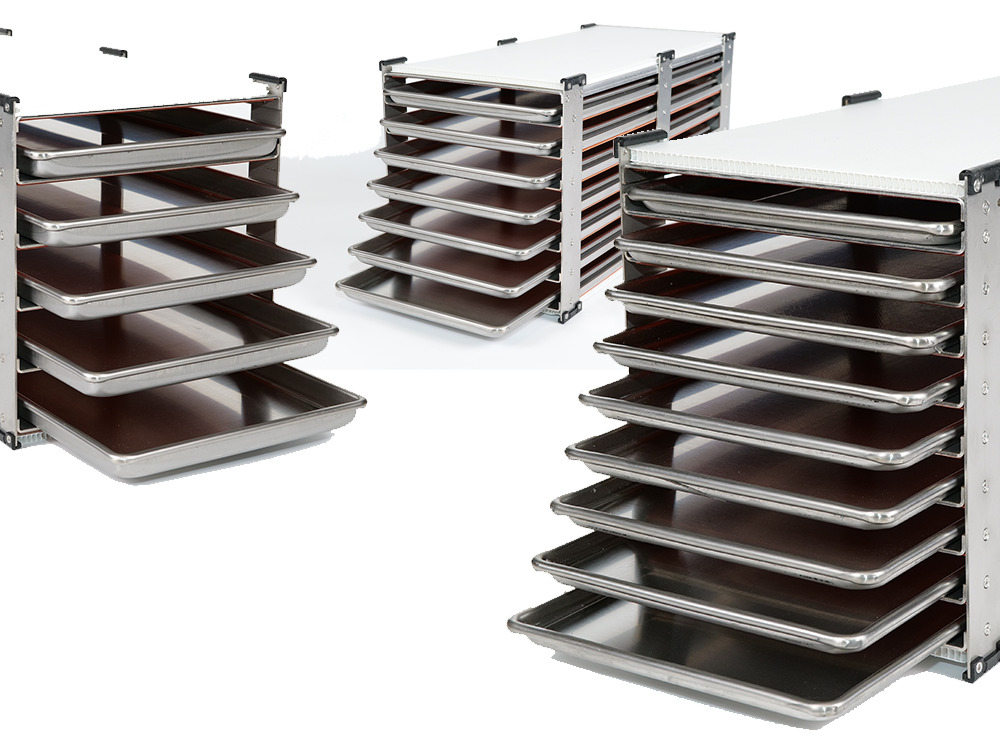

Our Xiros Mikro freeze dryer is a small freeze dryer with a large capacity for product, allowing you to speed up your batch processing times without taking up too much space in the lab. It has up to 9 shelves, an 8 kg capacity for ice and 4 kg sublimation in 24 hours. We recommend using an oil free vacuum pump with this Freeze Dryer.

When choosing a freeze dryer, it’s important to research and consider your specific needs and budget. With purchasing the right machine, you can ensure the quality and economic viability of your products.

Successful Freeze Drying: tips

Preparing Your Food for Freeze Drying

Proper preparation of the product you would like to freeze dry is essential in ensuring the desired outcome. Before you start the freeze drying process, it is important to ensure your food is fresh and high-quality. You should wash and cut fruits and vegetables correctly before processing them.

For vegetables: detach the stems and leaves, then chop them into small, uniform pieces for a more efficient drying process. However, should you require the stems/branches to be dried too, feel free to leave them intact. Bear in mind, though, that this will extend the drying duration.

For fruits: ensure that you remove any bruised or damaged parts. For vegetables: remove the stems and leaves and cut them into small, uniform pieces.

It is also possible to blanch your fruits and vegetables before freeze drying them. Blanching helps preserve the food’s color, flavor, and nutrients. To whiten your food, immerse it in boiling water for a few minutes and then transfer it to a bowl of ice water to stop cooking. Once the food is cool, pat it dry with a paper towel to remove excess water before placing it in the freeze dryer.

Operating Your Freeze dryer

It’s essential to set up the machine correctly and follow the instructions specified in the user manual. Before you start the freeze drying process, ensure the machine is clean. Also, ensure that the trays are properly arranged for proper temperature and air circulation during the process.

It’s important to control the temperature, pressure, and time within the recommended parameters for optimal results. The temperature (heat and cold) should be set to the appropriate level for the type of food you are freeze drying. The pressure should also be monitored to ensure it remains within the recommended range. The time required for freeze drying varies depending on the type of food, so it’s essential to follow the recommended time for your product. With our Xiros Mikro you have automatic settings for these parameters and program up to 16 separate steps

Fun fact: The entire freeze drying method takes 9–24 hours, while conventional drying can take several weeks to complete. That saves a lot of time and retains many precious product features.

Check out the details of the Xiros Mikro freeze dryers.

Storing Freeze Dried Products

Once the product is freeze dried, it’s essential to store it correctly to ensure its long-term storage. The best way to keep freeze dried products is in airtight containers in a cool, dry place. Ensure that the containers are labeled with the date of freeze drying and the type of food to avoid confusion.

It’s also important to protect your freeze dried products from moisture and light. Moisture can cause the food to spoil, while light can cause the color and flavor of the food to deteriorate. Therefore, store your freeze dried products in a dark, dry place away from any sources of moisture.

By following the tips outlined above, you can ensure that your freeze-dried products are of high quality and have a long shelf life.

Freeze drying: Conclusion

Embrace the benefits of freeze drying

In wrapping up, freeze drying isn’t just a technique; it’s an innovative revolution for industries across the board—from food and pharmaceuticals to biotechnology. With its unique ability to extend shelf life, prevent waste, retain taste and texture, and preserve nutritional integrity, it’s more than an investment—it’s a strategy for superior outcomes. Like our Xiros Mikro, the right freeze dryer can become a crucial cornerstone of your operational excellence.

In the UK or elsewhere, ready to unlock these powerful benefits? The next step in your journey of innovation awaits. Explore our line of Xiros Mikro freeze dryers through our trusted distributors.

Visit us at:

https://hollandgreenscience.eu/distributors/

We’re just a call or an email away for any inquiries or further assistance.

Contact us by calling +31 643 498 156

or send us an email at saleseurope@hollandgreenscience.com.

To stay in the loop with our latest updates, innovations, and events, follow us on LinkedIn and Instagram!

Let’s explore a freeze-dried future together!