Freeze drying, or lyophilization, has emerged as a crucial method for food preservation, enabling extended shelf life while retaining nutritional value. However, it is important to note that improper handling can lead to foodborne illness, as freeze-drying does not eliminate microorganisms. This technique has gained popularity among Michelin-starred chefs, commercial food producers, home cooks, farmers, confectioners, and survivalists. Ensuring food safety and environmental sustainability in freeze-drying equipment is essential. Compliance with Hazard Analysis and Critical Control Point (HACCP) guidelines and standards plays a vital role in safeguarding consumers and the environment.

Introduction to Freeze Drying in the Food Business

Freeze drying, also known as lyophilization, is a popular method of food preservation that involves removing the water content from food products by freezing and then reducing the surrounding pressure to allow the frozen water to sublimate directly into a gas. This process helps to preserve the nutritional value, texture, and flavour of the food, making it a valuable technique in the food business.

In the food industry, freeze drying is used to produce a wide range of products, from fruits and vegetables to meats and gourmet ready-to-eat meals. While commercial producers value its efficiency, culinary innovators and fine-dining chefs appreciate the technique for its ability to preserve the true essence of ingredients — their texture, flavour, and nutritional integrity — opening doors to creative and sustainable gastronomy.

The freeze drying process involves several critical control points, including freezing, primary drying, and secondary drying. Each stage must be carefully controlled to ensure the quality and safety of the final product. During the freezing stage, the food is rapidly frozen to form ice crystals. In the primary drying phase, the pressure is reduced, and heat is applied to sublimate the ice crystals directly into vapor. Finally, the secondary drying phase, also known as desorption drying, removes any remaining moisture to achieve the desired level of dryness.

By adhering to these critical control points, producers can ensure safe, shelf-stable products while preserving the concentrated essence of each ingredient — a quality that appeals to both discerning consumers and visionary chefs seeking depth of flavour and creative potential.

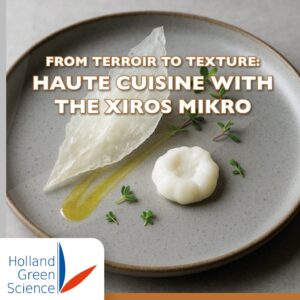

Beyond Preservation – A Tool for Culinary Creativity

In recent years, freeze drying has also found its way into the world of fine dining and gastronomy. Michelin-starred chefs and innovative food creators have discovered that lyophilization is not only a preservation technique, but also a tool for flavour exploration and creative presentation. Because freeze drying intensifies natural aromas and tastes, chefs can transform ingredients into lightweight, shelf-stable powders, crystals, or sheets — perfect for adding concentrated flavour or unexpected textures to a dish. Think of a vibrant beetroot powder dusted over a carpaccio, or a delicate citrus crystal hidden inside a dessert that releases a burst of aroma with every bite.

With equipment like the Xiros Mikro GEN2 freeze dryer, chefs can explore the limits of taste design, turning science into a source of culinary artistry and innovation.

The freeze drying process involves several critical control points, including freezing, primary drying, and secondary drying. Each stage must be carefully controlled to ensure the quality and safety of the final product. During the freezing stage, the food is rapidly frozen to form ice crystals. In the primary drying phase, the pressure is reduced, and heat is applied to sublimate the ice crystals directly into vapor. Finally, the secondary drying phase, also known as desorption drying, removes any remaining moisture to achieve the desired level of dryness.

By adhering to these critical control points, food businesses can produce freeze-dried products that are safe for consumption and have an extended shelf life, meeting the demands of consumers for convenient and long-lasting food options.

HACCP Certification and Its Importance in Food Safety and Preservation

HACCP is a systematic, preventive approach to food safety that identifies and mitigates potential hazards in food production. It is crucial to handle raw foods and raw meat properly to prevent contamination and ensure safety when you are freeze drying. This certification ensures that freeze dryers are designed and operated to minimize risks associated with microbial contamination, spoilage, and volatile organic compounds (VOCs). The vacuum conditions in freeze drying can cause VOCs from adhesives, electrical wiring, and heaters to deposit on food, potentially leading to adverse health effects.

Key Principles of HACCP

- Hazard Analysis: Identifying biological, chemical, and physical hazards that could compromise food safety.

- Critical Control Points (CCPs): Establishing points in the process where controls can be applied to mitigate hazards. It is crucial to keep raw meat, poultry, seafood, and eggs separate from ready to eat foods to prevent contamination.

- Critical Limits: Setting maximum or minimum values for CCPs to ensure food safety.

- Monitoring Procedures: Implementing processes to track and maintain control over CCPs.

- Corrective Actions: Defining steps to address deviations from critical limits.

- Verification Procedures: Ensuring the HACCP system effectively prevents food safety risks.

- Record Keeping: Documenting procedures and monitoring activities to maintain compliance.

The Importance of HACCP Certification for the Freeze Drying Process

Health Protection: Reduces contamination risks from microbes and harmful VOC exposure.

Consistent Quality: Ensures reliable performance and superior taste and nutrition in freeze-dried foods.

Regulatory Compliance: Aligns businesses with stringent food safety standards to prevent legal issues and recalls.

Holland Green Science is proud to announce that our Xiros Mikro GEN2 Freeze Dryer has successfully achieved HACCP certification following rigorous third-party testing. This certification reassures customers of our commitment to food safety and product excellence. HACCP certification plays a crucial role in ensuring the safety and quality of freeze dried food, making it suitable for various applications including military rations and space missions.

Freeze Dryer Equipment and Maintenance

Freeze dryer equipment is a critical component of the freeze drying process, and proper maintenance is essential to ensure the quality and safety of the final product. Freeze dryers are designed to operate under precise temperature and pressure conditions, and any malfunction or failure can result in contamination or spoilage of the product.

Regular maintenance of freeze dryer equipment includes cleaning and sanitizing the equipment, checking for any signs of wear or damage, and performing routine tests to ensure that the equipment is functioning correctly. It is crucial to follow the manufacturer’s instructions for maintenance and repair, and to keep accurate records of all maintenance and repair activities. This documentation helps in tracking the equipment’s performance and identifying any potential issues before they become critical.

In addition to regular maintenance, it is also important to ensure that the freeze dryer equipment is properly calibrated and validated to ensure that it is operating within the required parameters. This includes checking the temperature and pressure controls, as well as the vacuum system, to ensure that they are functioning correctly. Proper calibration ensures that the freeze drying process is consistent and reliable, producing high-quality freeze-dried products every time.

By prioritizing regular maintenance and calibration, food businesses can ensure that their freeze dryer equipment operates efficiently and effectively, minimizing the risk of contamination and ensuring the safety and quality of their freeze-dried products.

Conclusion

HACCP compliance is a essential pillar for responsible food processing, production, preservation and sustainable manufacturing. By prioritizing food safety and environmental standards, freeze dryer manufacturers can offer products that protect consumers and the planet.

At Holland Green Science, we are proud to lead the industry with our Xiros Mikro GEN2 Freeze Dryer, ensuring the highest standards of food safety and environmental responsibility. Through continuous innovation and compliance, we are committed to delivering safe, sustainable, and high-quality freeze-drying solutions for businesses and home users alike.

References

- National Advisory Committee on Microbiological Criteria for Foods (NACMCF)

- Food and Drug Administration (FDA) Guidelines on HACCP

- International Organization for Standardization (ISO) Standards on Food Safety Management

- European Commission RoHS Directive (2011/65/EU)