In today’s fast-paced world, the convenience of long-lasting, flavourful, and nutritious food has become increasingly important. One of the most innovative ways to achieve this is through freeze drying—a process that locks in all the essential qualities of food while preserving it for extended periods. But why does this method, especially using high-end machines like the Xiros Mikro from Holland Green Science, take so much time? And more importantly, why is it crucial to go through each step with precision?

At Holland Green Science, we believe that freeze drying is an art as much as it is a science. It’s about understanding the complexity of each product, the delicacy of each step, and the promise that our customers can achieve the ultimate preservation. This blog will take a deep dive into the details of why freeze drying takes time, what can go wrong, and how the Xiros Mikro freeze dryer, with its 16 programmable steps, is the key to unlocking the future of food preservation.

Why does Freeze Drying has to take so much time? Understanding the Process

Freeze drying, or lyophilization, involves three key stages: freezing, primary drying (sublimation), and secondary drying (desorption). Each of these stages must be carefully controlled to ensure the preservation of the food’s texture, flavour, and nutritional value.

Freeze drying food is highly beneficial for food preservation and portability, making it an excellent choice for backpacking and other outdoor activities.

-

Freezing Stage: The product is frozen, usually between -20°C and -30°C, to convert water into ice and to freeze the product.

-

Primary Drying (Sublimation): Under a vacuum, the frozen water is removed directly from the solid (ice) phase to vapor, bypassing the liquid phase.

-

Secondary Drying (Desorption): Any remaining bound water is removed by raising the temperature gently under a lower vacuum.

This process may sound simple, but the reality is that it takes a great deal of time, often stretching into hours or even days depending on the type of product being freeze-dried. So why does it take so long?

Definition and Brief History of Freeze Drying

Freeze drying, also known as lyophilization, is a low-temperature dehydration process that involves freezing the product, lowering pressure, and then removing the ice by sublimation. This method is highly effective in preserving the structural integrity, flavour, and nutritional value of various products, making it a preferred choice in food processing technology and pharmaceuticals.

The origins of freeze drying can be traced back to the early 20th century. During World War II, the process was used to preserve blood plasma and penicillin for soldiers, marking its first significant application. Over the decades, advancements in technology have refined the freeze drying process, making it more efficient and accessible. Today, modern freeze dryers, like the Xiros Mikro, offer precise control over the drying process, ensuring high-quality preservation of a wide range of products.

Stages of the Freeze Drying Process

The freeze drying process is meticulously divided into three critical stages: freezing, primary drying (sublimation), and secondary drying (desorption). Each stage plays a vital role in ensuring the final product retains its original qualities.

-

Freezing Stage: In this initial phase, the product is usually frozen to a temperature between -20°C and -30°C. This step is crucial as it converts the water content in the product into ice, forming ice crystals that help maintain the product’s structure.

-

Primary Drying (Sublimation): During this stage, the freeze dryer creates a vacuum, causing the ice to sublimate directly from solid to vapor without passing through the liquid phase. This sublimation process is slow and requires precise control of temperature and pressure to prevent the ice from melting, which could compromise the product’s quality.

-

Secondary Drying (Desorption): The final stage involves removing any remaining bound water molecules by gently raising the temperature under a lower vacuum. This step ensures that the product is thoroughly dried, enhancing its shelf life and stability.

By carefully managing each stage, the freeze drying process effectively preserves the product’s texture, flavour, and nutritional value, making it an indispensable technique in food processing and pharmaceuticals.

What Happens If You Rush the Freeze Drying Process?

It might be tempting to speed up the freeze drying process to save time. However, doing so risks ruining the final product. When steps are rushed or executed poorly, the freeze drying process is disrupted, and effectively ruining your product before the process is done. When this has happened (When temperatures are rushed (to hot) the water in the frozen product and or the product itself is not frozen anymore, then ice has become liquid water and when that evaporates your freeze dried products will lose its flavour, texture, or even its nutritional value. Here’s how cutting corners can impact the process:

Rushing the Freezing Stage:

-

If you freeze the product too quickly (for instance with liquid nitrogen) you will get small ice crystals who will lead to a slower freeze drying process.

-

Inadequate freezing can also result in some parts of the product being too warm so not fully frozen, which will result in improper lyophilization (freeze drying) during the sublimation phase. So this is actually inadequate freeze drying, since the product is not entirely frozen. Yes, your products can become dry in the end, but you will loose the benefit of the whole freeze drying process, in fact your more heat drying (oven drying) at that point. One good indicator of this incorrect freeze drying is the presence of exes of terpenes and flavour in your condenser and there for in the drain water. In short the more terpenes in your drain water, the more your freeze drying process is incorrect and needs to be adjusted to the right settings.

Speeding Up Sublimation (Primary Drying):

-

Sublimation is a slow process that must be meticulously controlled. If you try to speed it up by raising the temperature too quickly, you risk causing the ice to melt instead of sublimating.

-

This will lead to a loss of flavour and aroma, as heat-sensitive compounds, such as terpenes, evaporate at higher temperatures. Terpenes are crucial for the flavour profile and aroma of many fruits and herbs, and losing them would drastically reduce the quality of the product. As mentioned before, in the end your product is not really a result of freeze drying, it’s more comparable to normal or oven drying.

Shortening the Secondary Drying (Desorption):

-

In the final stage, any bound water that remains in the product needs to be carefully removed. Rushing this stage by raising the temperature too quickly can cause unwanted chemical reactions, leading to a not fully dried product, you can’t call it a real freeze dried product at that stage any more. And you will encounter the loss of taste, aroma, and nutritional value. Additionally, storing improperly preserved food at too high a temperature can lead to the growth of harmful bacteria, compromising both the quality and safety of the food product.

Thus, taking time in each phase is essential. By properly controlling temperature, vacuum levels, and timing, you preserve not only the food’s structure but also its flavour, aroma, and nutritional integrity.

The Role of Programmable Steps in Perfect Freeze Drying

One of the main reasons freeze drying is a time-consuming process is the need to fine-tune each phase, including primary and secondary drying, depending on the specific product. Each food type has its own unique combination of properties—like thickness, sugar content, fat, and salt levels—that determine how quickly or slowly it should be freeze-dried.

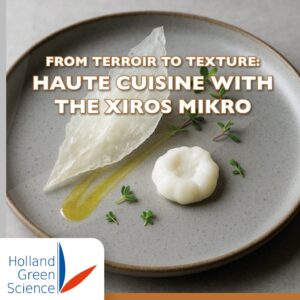

This is where the Xiros Mikro freeze dryer by Holland Green Science comes into play. Unlike other freeze dryers on the market, the Xiros Mikro allows users to precisely control the process using up to 16 programmable steps. This means that each phase of the freeze-drying process can be tailored specifically to the product being dried.

What else is important?

Thickness of the Product:

-

Thicker products require more time in the freezing and sublimation stages to ensure that all the water is properly frozen and then removed. The freezing temperature plays a critical role in the freeze-drying process, as it influences the structure of the material and factors like ice crystal formation, which are essential for optimizing drying times and maintaining the integrity of the materials. With the Xiros Mikro, you can adjust the duration of each step to suit the thickness of your product. 5mm or less is the preferred slice thickness.

Sugar Content:

-

High-sugar products, like fruits, are more delicate during freeze drying. Too much heat during desorption can cause the sugar to caramelize, affecting flavour and colour. By setting precise temperature controls, the Xiros Mikro prevents such mishaps.

Salt and Fat Content:

-

Products with high salt or fat content dry differently than others. Salt can slow down the drying process, while fats can cause uneven drying. The Xiros Mikro’s programmable settings allow you to adjust the vacuum and temperature specifically to handle such challenges, ensuring a perfectly dried product almost every time. If the fat content is to high it is impossible to freeze dry.

Freeze dried food after the drying process

Applications of Freeze Drying

Freeze drying has a wide range of applications across various industries, thanks to its ability to preserve the quality and extend the shelf life of products.

-

Food Industry: Freeze drying is extensively used to preserve fruits, vegetables, and meats. The process locks in the flavour, aroma, and nutritional value, making freeze dried food a popular choice for consumers seeking high-quality, long-lasting products. From camping meals to emergency food supplies, or even for space missions to provide astronauts with nutritious and lightweight food options. freeze dried food offers convenience without compromising on taste or nutrition.

-

Pharmaceutical Industry: In the pharmaceutical sector, freeze drying is crucial for preserving vaccines, antibiotics, and other sensitive medications. The low temperature dehydration process ensures that these products remain stable and effective over extended periods, which is essential for maintaining their therapeutic properties.

-

Other Applications: Beyond food and pharmaceuticals, freeze drying is also used in biotechnology for preserving biological samples and florists that can dry a memorable bouquet, such as a bridal or farewell bouquet, so this same bouquet can be enjoyed for many years to come. The versatility of freeze drying makes it a valuable tool in various fields, where maintaining the integrity and longevity of products is paramount.

By understanding the freeze drying process and its diverse applications, we can appreciate the technology’s role in enhancing the quality and sustainability of products across multiple industries.

What Makes the Xiros Mikro Unique?

At Holland Green Science, we understand that each freeze-drying process is unique. The Xiros Mikro freeze dryer has been designed with versatility and precision in mind, making it the ideal tool for customers who are serious about food preservation. One of its standout features is the advanced vacuum control, which relies on a two-stage rotary vacuum pump to maintain the necessary vacuum for effective solvent removal. This ensures optimal performance and reliability during the drying process. But what makes this machine stand out from the rest?

Key Features of the Xiros Mikro:

-

16 Programmable Steps: Allows for precise control over every aspect of the process, from freezing to drying. No two foods are alike, and the Xiros Mikro lets you tailor the process to each product’s unique requirements.

-

Advanced Vacuum Control: Ensures that the sublimation process occurs at the correct rate, preventing ice from melting and damaging the product.

-

Temperature Precision: With the ability to control temperatures to within a fraction of a degree, the Xiros Mikro ensures that heat-sensitive compounds, like terpenes, are preserved.

-

Energy Efficiency: The Xiros Mikro is designed to be energy-efficient, making it not only a powerful freeze dryer but also a sustainable option for long-term food preservation.

By embracing the Xiros Mikro, you’re not just buying a freeze dryer—you’re investing in a future where quality, efficiency, and preservation go hand in hand. It’s a lifestyle choice for those who care about maintaining the flavour, aroma, and nutritional value of their food.

Real-Life Impact: Stories from Xiros Mikro Users

For many of our customers, the Xiros Mikro has transformed the way they approach food preservation. Here are a few real-world examples of how this innovative machine has helped users achieve perfect results:

-

Maximizing Flavours in Herbs and Spices: One Xiros Mikro user, a small-scale spice producer, shared how the programmable steps allowed them to retain the rich terpenes in their herbs. Before switching to the Xiros Mikro, they struggled with losing key aromatic compounds during drying. All terpenes ended up in the drain water after the defrost. Now, they can precisely control the temperature and vacuum to lock in those flavours. No need to win them back from the drain water, they are still in the product!

-

Preserving Nutrients in Vegetables: A health-conscious consumer focused on preserving their homegrown vegetables praised the Xiros Mikro for allowing them to retain up to 97% of the vitamins and minerals in their produce. The ability to customize the drying process for different vegetables, especially during the primary drying phase where meticulous control over heat and pressure is critical, meant they could enjoy nutrient-packed meals year-round.

Conclusion: Unlock the Future of Freeze Drying with the Xiros Mikro

Freeze drying takes time because it’s an intricate process that requires precision at every stage. Each phase—from freezing to sublimation to desorption—must be carefully managed to preserve the flavour, texture, and nutritional value of the food. Rushing this process leads to inferior results, with flavour loss, texture degradation, and a reduced nutritional profile.

But with the right tools, like the Xiros Mikro freeze dryer from Holland Green Science, you can take full control of the freeze-drying process, preserving everything that makes food delicious and nutritious. Whether you’re drying fruits, herbs, or even high-fat products, the Xiros Mikro allows you to adjust every aspect of the process for perfect results every time.

By taking the time to freeze dry properly—and using the best machine on the market—you’re not just preserving food; you’re preserving flavour, health, and sustainability for the future. Additionally, freeze drying food offers significant benefits for food preservation and portability, making it an ideal solution for backpacking and other outdoor activities.